Page 244 - ANTEST KATALOG

P. 244

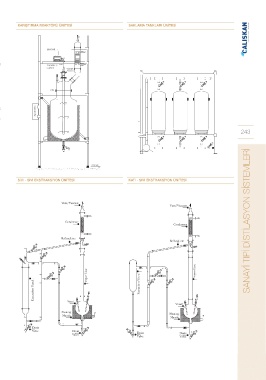

KARIŞTIRMA REAKTÖRÜ ÜNITESI SAKLAMA TANKLARI ÜNITESI

LIQUID-LIQUID EXTRACTION UNIT

Liquid extraction, sometimes called solvent extraction, is the separation of

constituents of a liquid solution by contact with another insoluble liquid.

The unit described here is for a semi-batch operation.

The liquid to be extracted is poured into an extraction vessel. Solvent is

boiled in a reboiler vessel and condensed in an overhead condenser, the

condensed liquid collected in a reflux divider and passed through pipework

to the extraction vessel. The pipework incorporates valves in order that the

solvent can enter the extraction vessel at either the base of the top,

depending on the relative densities of the solvent and liquid to be

extracted. The solvent and the extracted liquid pass back to the reboiler and

the process is repeated until the extraction is complete. The extraction

vessel is then drained and the solvent evaporated from the reboiler vessel

and collected in the extraction vessel enables the two liquids to be drained

form their respective vessels.

The unit is available in vessel sizes of 10, 20, & 50L and is suitable for 243

operation under atmoshepric pressure.

REACTOR BATH VAPOUR EXTRACTION CONDENSER UNIT

CAPACITY KW LINE VESSEL M2 CAT. REF.

10 L 3 40mmx1m 10 L 0.35 ALLU 10

20 L 4.5 50mmx1m 20 L 0.5 ALLU 20

50 L 6 80mmx1m 50 L 1.5 ALLU 50

SIVI - SIVI EKSTRAKSIYON ÜNITESI KATI - SIVI EKSTRAKSIYON ÜNITESI

LIQUID-LIQUID EXTRACTION UNIT SOLID LIQUID EXTRACTION UNIT

Liquid extraction, sometimes called solvent extraction, is the separation of operation involves preferential solublising of one or more soluble

This

constituents of a liquid solution by contact with another insoluble liquid.

constituents (solutes) of a solid mixture by a liquid solvent. The unit

The unit described here is for a semi-batch operation. described here is for a semi-batch operation. SANAYİ TIPİ DİSTİLASYON SİSTEMLERİ

The liquid to be extracted is poured into an extraction vessel. Solvent is

The solid to be extracted is put inside a glass fiber bag and placed in an

boiled in a reboiler vessel and condensed in an overhead condenser, the

extraction vessel. Solvent from the reboiler is continuously

condensed liquid collected in a reflux divider and passed through pipework

evaporated,condensed and circulated through a reflux divider by means of

to the extraction vessel. The pipework incorporates valves in order that the

piping network and valves. When desired/ steady concentration of solute is

solvent can enter the extraction vessel at either the base of the top,

achieved in the solution the operation is discontinued. The solution is

depending on the relative densities of the solvent and liquid to be

drained off and collected for further use.

extracted. The solvent and the extracted liquid pass back to the reboiler and

After charging fresh solid in fiber bag and solvent in reboiler, the cycle can

the process is repeated until the extraction is complete. The extraction

be restarted again.The unit is available in vessel sizes of 10, 20, & 50L and is

vessel is then drained and the solvent evaporated from the reboiler vessel

suitable for operation under atmospheric pressure.

and collected in the extraction vessel enables the two liquids to be drained

form their respective vessels.

The unit is available in vessel sizes of 10, 20, & 50L and is suitable for BATH VAPOUR EXTRACTION CONDENSER UNIT

REACTOR

operation under atmoshepric pressure. CAPACITY KW LINE VESSEL M2 CAT. REF.

10L 3 40mmx1m 10 L 0.35 ASLU10

REACTOR BATH VAPOUR EXTRACTION CONDENSER UNIT 20L 4.5 50mmx1m 20 L 0.5 ASLU20

CAPACITY KW LINE VESSEL M2 CAT. REF. 50L 6 80mmx1m 50 L 1.5 ASLU50

10 L 3 40mmx1m 10 L 0.35 ALLU 10

20 L 4.5 50mmx1m 20 L 0.5 ALLU 20

50 L 6 80mmx1m 50 L 1.5 ALLU 50

SOLID LIQUID EXTRACTION UNIT

This operation involves preferential solublising of one or more soluble

85

constituents (solutes) of a solid mixture by a liquid solvent. The unit

described here is for a semi-batch operation.

The solid to be extracted is put inside a glass fiber bag and placed in an

extraction vessel. Solvent from the reboiler is continuously

evaporated,condensed and circulated through a reflux divider by means of

piping network and valves. When desired/ steady concentration of solute is

achieved in the solution the operation is discontinued. The solution is

drained off and collected for further use.

After charging fresh solid in fiber bag and solvent in reboiler, the cycle can

be restarted again.The unit is available in vessel sizes of 10, 20, & 50L and is

suitable for operation under atmospheric pressure.

REACTOR BATH VAPOUR EXTRACTION CONDENSER UNIT

CAPACITY KW LINE VESSEL M2 CAT. REF.

10L 3 40mmx1m 10 L 0.35 ASLU10

20L 4.5 50mmx1m 20 L 0.5 ASLU20

50L 6 80mmx1m 50 L 1.5 ASLU50

85