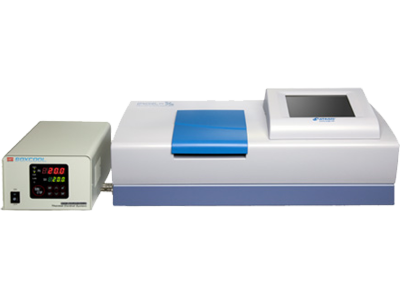

The “PLF-FF” series furnaces which are fiber free at their hot surface. This series is especially designed for Customers who are anxious of contamination due to flaking of the fiber insulation.

PLF SERİSİ

PLF-FF series furnaces can now be ordered for a small extra charge for the more delicate firing operations. PLF-FF series furnaces are exactly the same of PLF series furnaces in their technical and electrical specifications only their insulations are modified at their hot face to be fiber free. Thus the contamination risk, no matter how little, is totally eliminated.

Our standard range Protherm Chamber Furnaces covering a range from 1100°C to 1600°C, all of which are front loading for easy operation and double skin construction to maintain a cooler outer case. Upto 1300°C, open wire based models are produced. where the elements are supported on ceramic tubes. Important advantage of these models is that element change is very easy and economic. Low thermal mass insulation leads to a very impressive heat up rate as well as efficient insulation. For furnaces starting from 1400°C Kanthal Globar series Silicon Carbide heating elements are employed, maintaining a very long service life.

There is always a safety switch for any modality of Chamber Furnace we produce which isolates power when door is opened. Temperature control provided either by PID or Programmable PID controls depending on customer requirements. Chamber exhaust vent is a standart till 1300°C and should be specially required for furnaces over 1400°C. A vertical counter balanced door, keeps the hot insulation away from operator, while opening upwards. Typical applications include melting, thermal ageing, ceramics sintering, metal heat treatment chemical decomposition, thermal shock testing etc.